44,270 تومان

کالا موجود استموجودی انبار : 196 عدد

علاقه مندان : 15 نفر

وضعیت : فعال

تعداد مرجوعی : 0

دنبال کنندگان : 17 نفر

قدمت : 9 سال و 11 ماه و 16 روز

وزن : 43 گرم

کل فروش : 3705 عدد

تعداد سفارش ها : 865 سفارش

3 از 5.0 با 13 رای

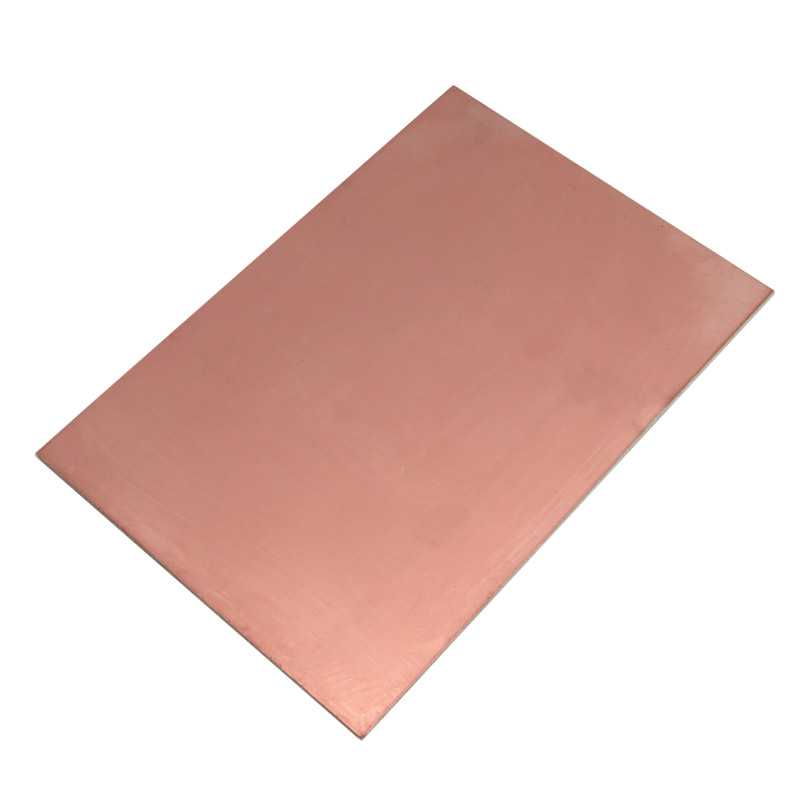

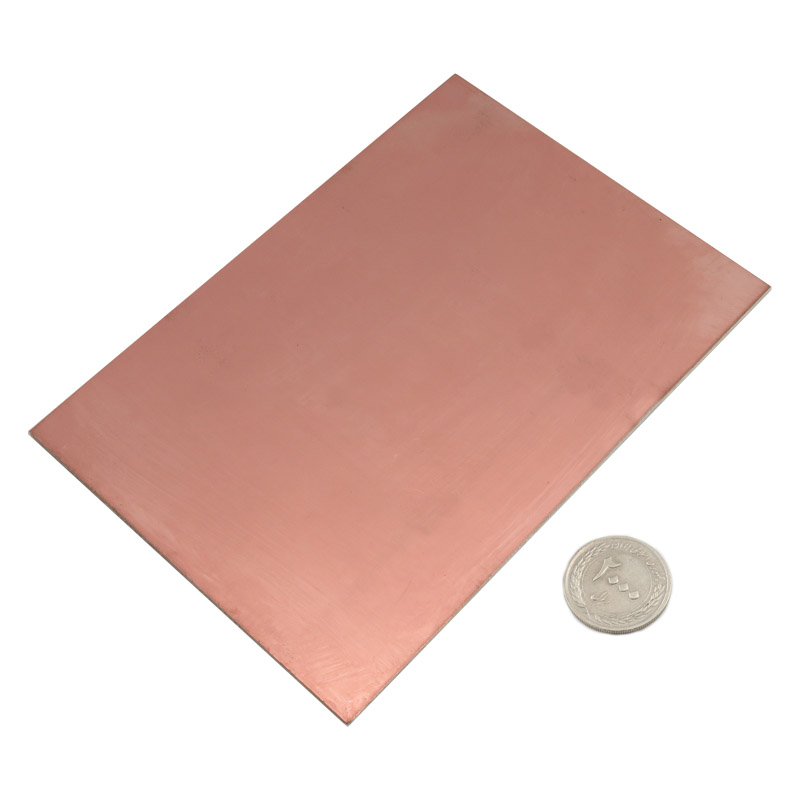

فیبر خام مدار چاپی یک رو 150x100 میلی متری استخوانی

برای طراحی بردهای الکترونیکی و ساخت انواع مدارهای الکترونیکی، بایستی طرح آن روی فیبر مدار چاپی پیاده سازی شود. فیبر مدار چاپی یا همان PCB دارای سطح مسی بسیار نازکی است. در حالت ساده فیبر مدار چاپی یک رو و فیبر مدار چاپی دورو وجود دارند. ولی در حالت حرفهای و صنعتی به بردهای چند لایه تبدیل میشوند. بُردهای مدار چاپی در همهٔ محصولات الکترونیکی حتی سادهترین آنها استفاده میشود. از دیگر وظایف بُرد مدار چاپی می توان به سیم بستهبندی و ساخت و ساز نقطه به نقطه اشاره کرد.

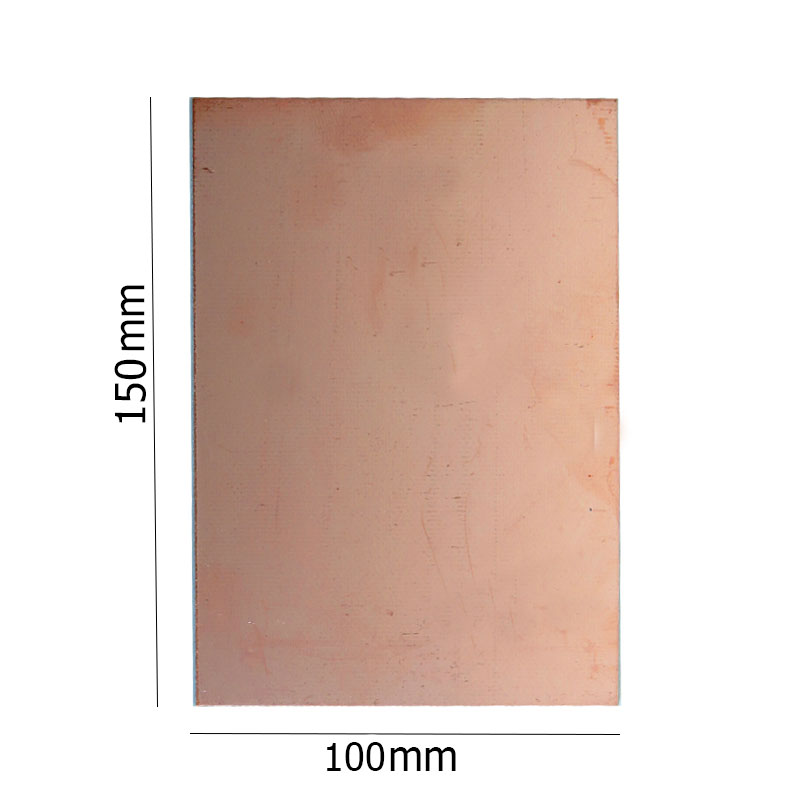

این برد مدار چاپی خام به صورت یک رو و دارای اندازه 10 در 15 سانتی متر است.

کاربرد :

- ساخت برد مدار چاپی (PCB)

مشخصات :

- نوع: فیبر PCB مسی تک طرفه

- اندازه: 10*15 سانتی متر

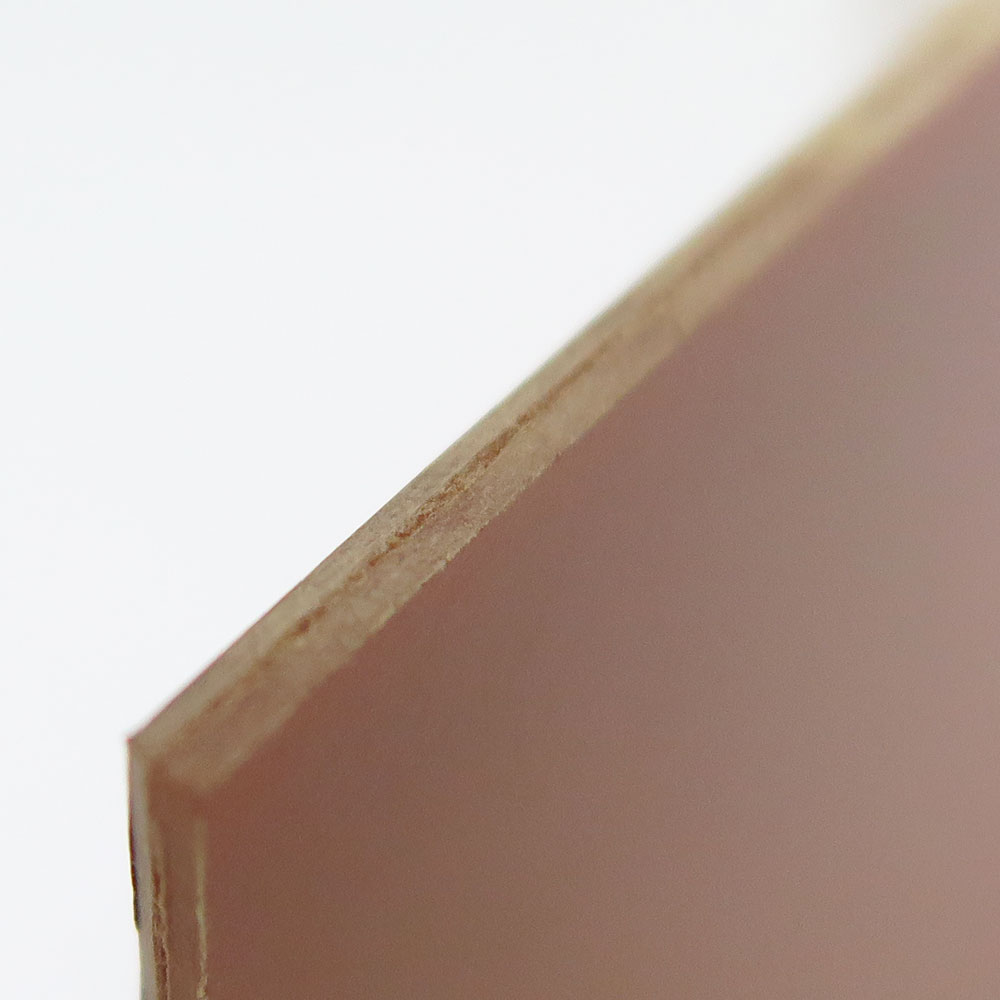

- جنس: استخوانی FR-4 مس

- ضخامت فیبر: 1.5 میلی متر