4 از 5.0 با 44 رای

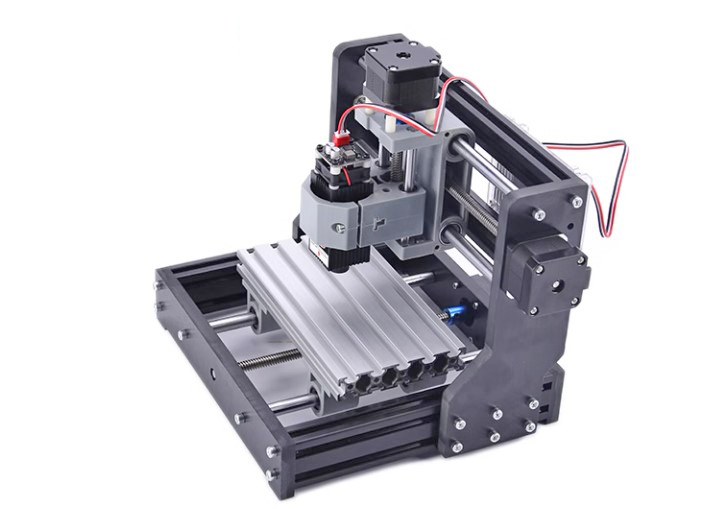

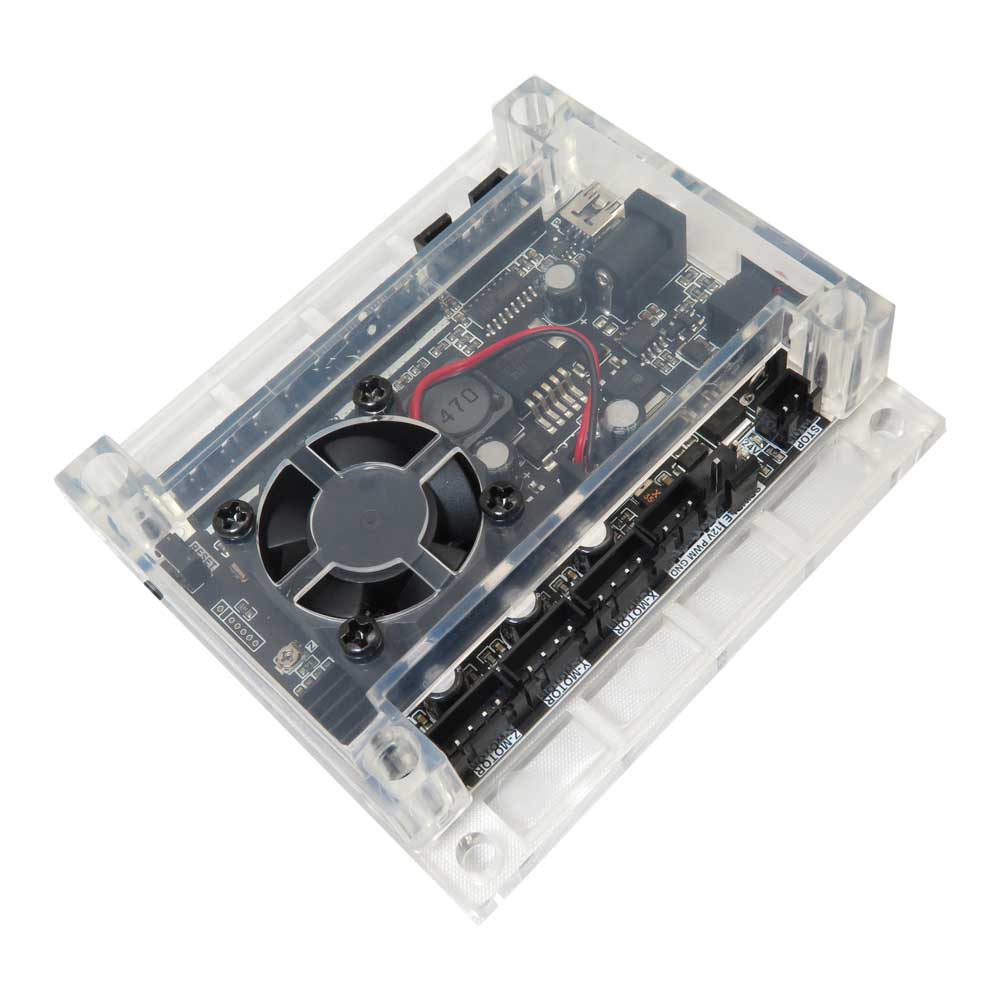

کیت دستگاه مینی سی ان سی با قابلیت حکاکی لیزر

***این دستگاه به صورت کیت ارائه می گردد.

کاربرد دستگاه مینی سی ان سی فرز :

- فرزکاری بردهای pcb

- برشکاری سوراخکاری هنری روی چوب

- ماشین کاری آلومینیوم، ام دی اف

مشخصات دستگاه مینی سی ان سی فرز:

- ابعاد پروفیل: 220 × 240 × 260 میلی متر

- صفحه حکاکی: 30 × 100 × 160 میلی متر

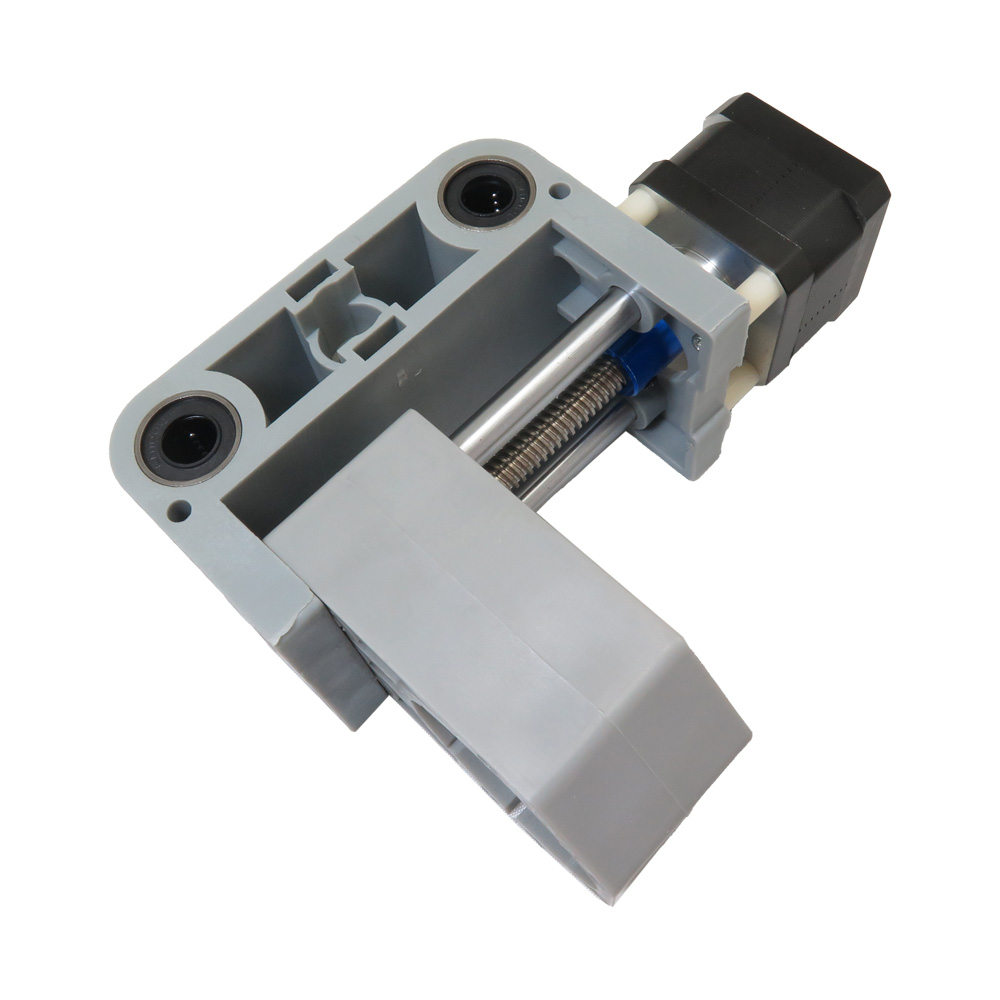

- پیچ لید حرفه ای T8،

- 4 میلی متری به همراه دو مهره مسی که برگشت به عقب و پس زنی را هنگام کار از بین می برد.

- استپر موتور: 42 استپر موتور جدید، کیفیت قابل اطمینان

- ولتاژ: 12 ولت

- جریان فاز: 1.3 آمپر

- مقاومت فاز اروپایی: 2.1

- گشتاور: 0.25 نیوتن متر

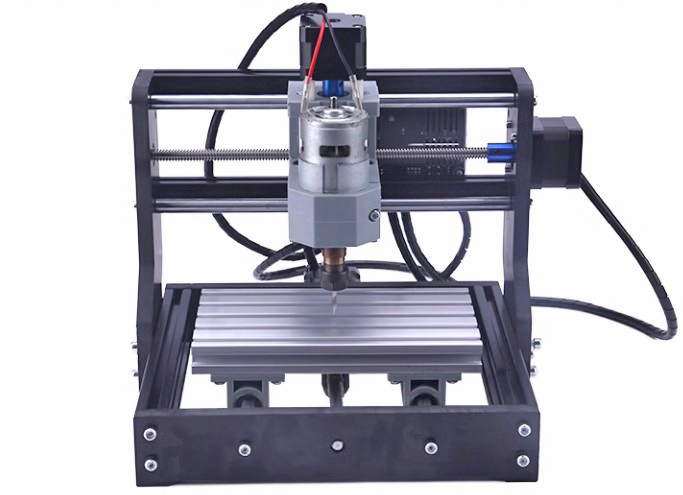

- اسپیندل: اسپیندل موتور 775 (36 ~ 12 ولت) 24ولتی با 7000 دور بر دقیقه و 36ولتی با 9000 دور بر دقیقه

- توان استپر موتور: آداپتور 12 ولتی، 3 آمپری

- توان موتور اسپیندل: اداپتور 24ولتی، 5 آمپری

- میز حکاکی: پروفیل آلومینیوم (20100) به اندازه 100 × 180

- فریم: پروفیل (2020)

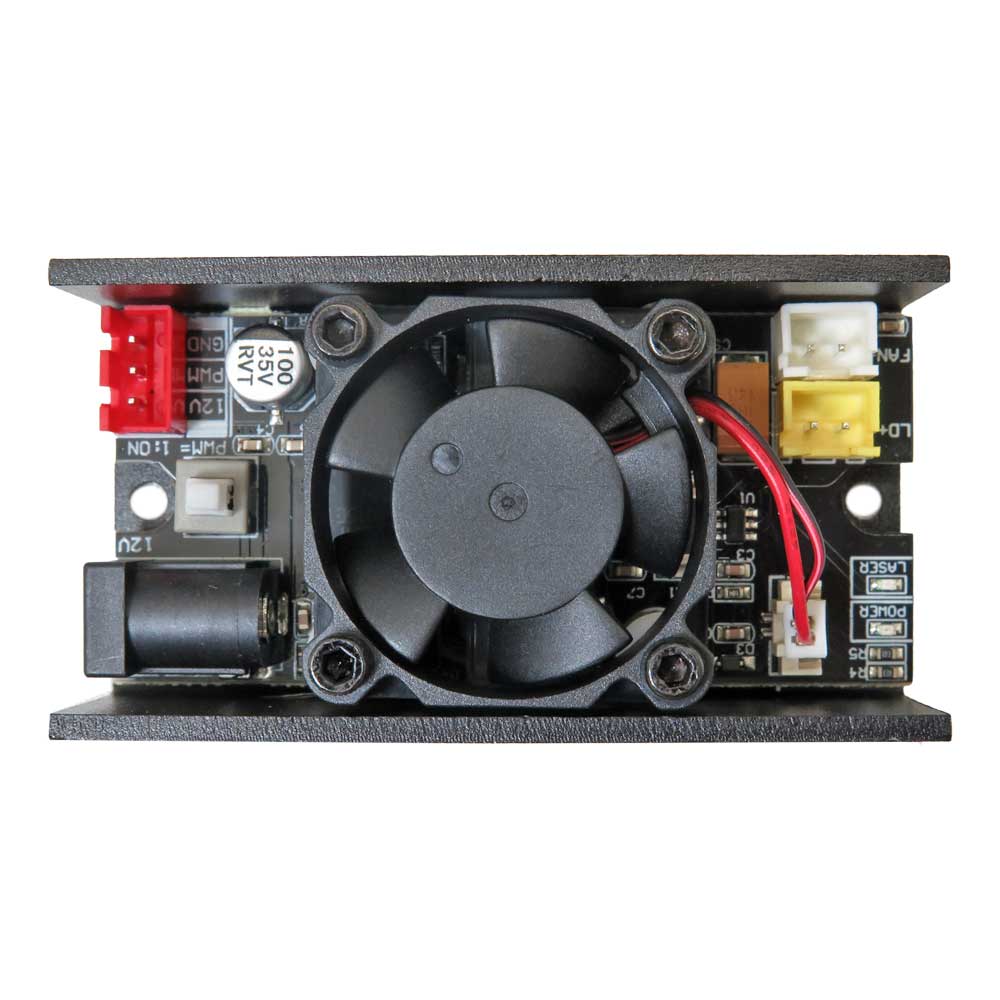

- توان لیزر : 7000 میلی وات(7 وات)

مستندات:

معرفی CNC1610

دانلود نرم افزار artcam دستگاه حکاکی لیزری

Features:

Profile Dimensions: 260x240x220mm (without motor projecting portion)

Stroke (Engraving area): 160x100x30mm

Screw: Professional T8 screw, lead 4mm, double copper nuts eliminating backlash

Stepper Motor: 42 New Reliable Stepper Motor

Voltage: 12V, Phase Current 1.3A, (2.1 European phase resistance)

Torque: 0.25N.m

Spindle: 775 Spindle Motor (12-36V) 24V: 7000r / min, 36V: 9000r / min

Power: Stepper Motor Power: 12V 3A adapter

Spindle Motor Power: 24V 5A adapter

Table: 20100 Profile (table size: 180x100mm)

Frame: 2020 Profiles

Laser Head: 12V 2500mw

Interface: USB

Software:

Control Software: GrblController

Toolpath Creation Software: Artcam2008 (Chinese Cracked Version)

PCB Processing Software: Coppercam (Chinese Cracked Version)

Features:

Profile Dimensions: 260x240x220mm (without motor projecting portion)

Stroke (engraving area): 160x100x30mm

Screw: Professional T8 screw, lead 4mm, double copper nuts eliminating backlash

Stepper motor: 42 new stepper motor. reliable quality

Voltage: 12V, phase current 1.3A, 2.1 European phase resistance, torque 0.25N.m

Spindle: 775 spindle motor (12-36V) 24V: 7000r / min, 36V: 9000r / min

Power: stepper motor power: 12V 3A adapter

Spindle motor power: 24V 5A adapter

Table: 20100 profile (table size: 180x100mm)

Frame: 2020 Profiles

12V2500mw laser head

Software:

Control Software: GrblController

Toolpath creation software: Artcam2008 (Chinese crack version)

PCB processing software: Coppercam (Chinese crack version)