350,450 تومان

در حال حاضر موجود نمی باشد

موجودی در حال ارسال به انبار

-

5 عدد1404/08/10

علاقه مندان : 14 نفر

وضعیت : فعال

تعداد مرجوعی : 0

دنبال کنندگان : 17 نفر

قدمت : 8 سال و 10 ماه و 19 روز

وزن : 55 گرم

کل فروش : 899 عدد

تعداد سفارش ها : 234 سفارش

5 از 5.0 با 5 رای

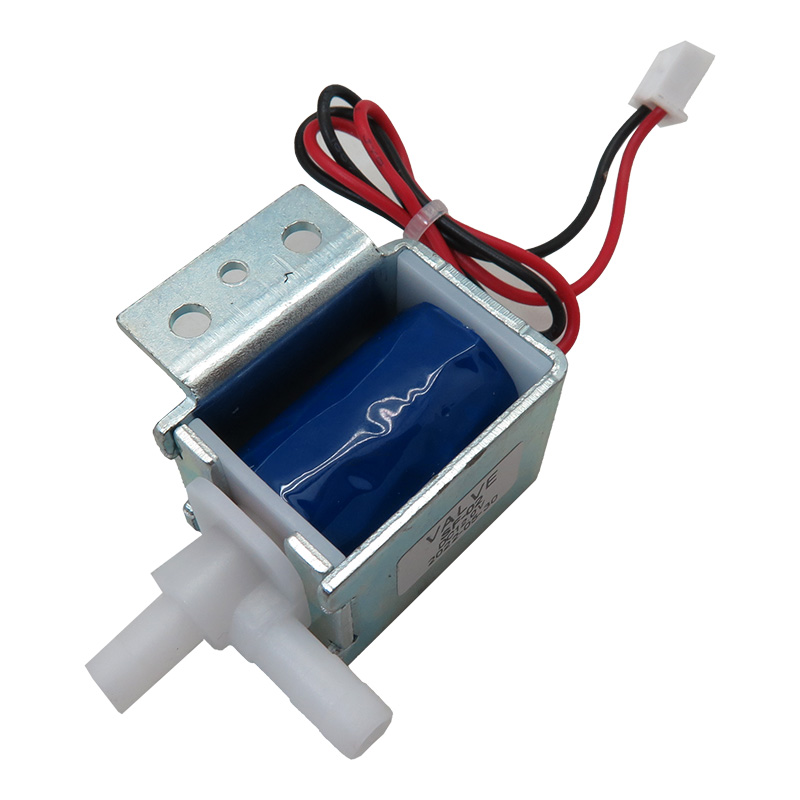

شیر برقی 12 ولتی 1.4w normally Open

شیر برقی یا همان solenoid valve قطعه ای است که در ابعاد مختلف از کوچک تا بزرگ ساخته میشود این محصول کاربردهای مختلفی در زمینه صنعت و مصارف خانگی دارد. در حقیقت این محصول به عنوان یک قطع کننده مسیر سیالاتی مانند مایعات و گازها به کار می رود.

نحوه کارکرد شیر الکتریکی به این شکل می باشد که زمانی که جریان برق به سیم پیچیده شده دور هسته فلزی یا همان کویل داخل شیر برقی وارد می شود. در سیم پیچ میدان مغناطیسی ایجاد می شود و باعث می شود که یک حالت مغناطیسی در سیم پیچ ایجاد شود و بوبین به میله آهنی که باعث باز یا بسته شدن مسیر مایعات می شود.

این شیر برقی آب 12 ولتی به صورت normally open و دارای توان 1.4 واتی است.

کاربرد شیر سلونوئیدی آب 12 ولت:

- آبیاری هوشمند

- کنترل خروجی منبع آب

- کشاورزی نوین

- صنایع

مشخصات شیر سلونوئیدی آب 12 ولت:

- ولتاژ: 12 ولت DC

- جریان: 0.14 آمپر

- محدوده فشار: 450 ~ 0 mmhg

- محدوده دمای کاری: 55 ~ 0 درجه سانتی گراد

- توان: کمتر از 3 وات

- طول خط: حدود: حدود 320 میلی متر

- طول پلاستیک سیلیکونی: حدود 200 میلی متر

مستندات:

کارکرد شیر برقی آب 12 ولتی

Description:

Solenoid valves differ in the characteristics of the electric current they use, the strength of the magnetic field they generate, the mechanism they use to regulate the fluid, and the type and characteristics of fluid they control. The mechanism varies from linear action, plunger-type actuators to pivoted-armature actuators and rocker actuators. The valve can use a two-port design to regulate flow or use a three or more port design to switch flows between ports. Multiple solenoid valves can be placed together on a manifold.

A solenoid valve is an electrically activated valve, typically used to control the flow or direction of air or liquid in fluid power systems. Solenoid valves are used in both pneumatic and hydraulic fluid power systems, and most often in either poppet or spool configurations.

All solenoid valves, no matter the design, are specified to be one of two general types: either a direct-acting valve or a pilot operated valve.

They are often used to replace manual valves or remote control. Solenoid valve function involves either opening or closing an orifice in a valve body, which either allows or prevents flow through the valve. A plunger opens or closes the orifice by raising or lowering within a sleeve tube by energizing the coil.

Application:

Pumping valve for breast pump

Atomizer

Solenoid valve for aromatherapy machine

Features:

Voltage: DC 12V

Current: 0.14 A

Pressure Range: 0-450mm/hg

Operating Temperature Range: 0 ℃ ~ 55 ℃

Power:

Line Length: about 320 mm

Silicone Tube Specifications : 4 x 7 mm

Silicone Tube Length: approx. 200 mm