1,322,460 تومان

کالا موجود استموجودی انبار : 87 عدد

علاقه مندان : 9 نفر

وضعیت : فعال

تعداد مرجوعی : 0

دنبال کنندگان : 14 نفر

قدمت : 10 سال و 15 روز

وزن : 146 گرم

کل فروش : 1053 عدد

تعداد سفارش ها : 269 سفارش

4 از 5.0 با 31 رای

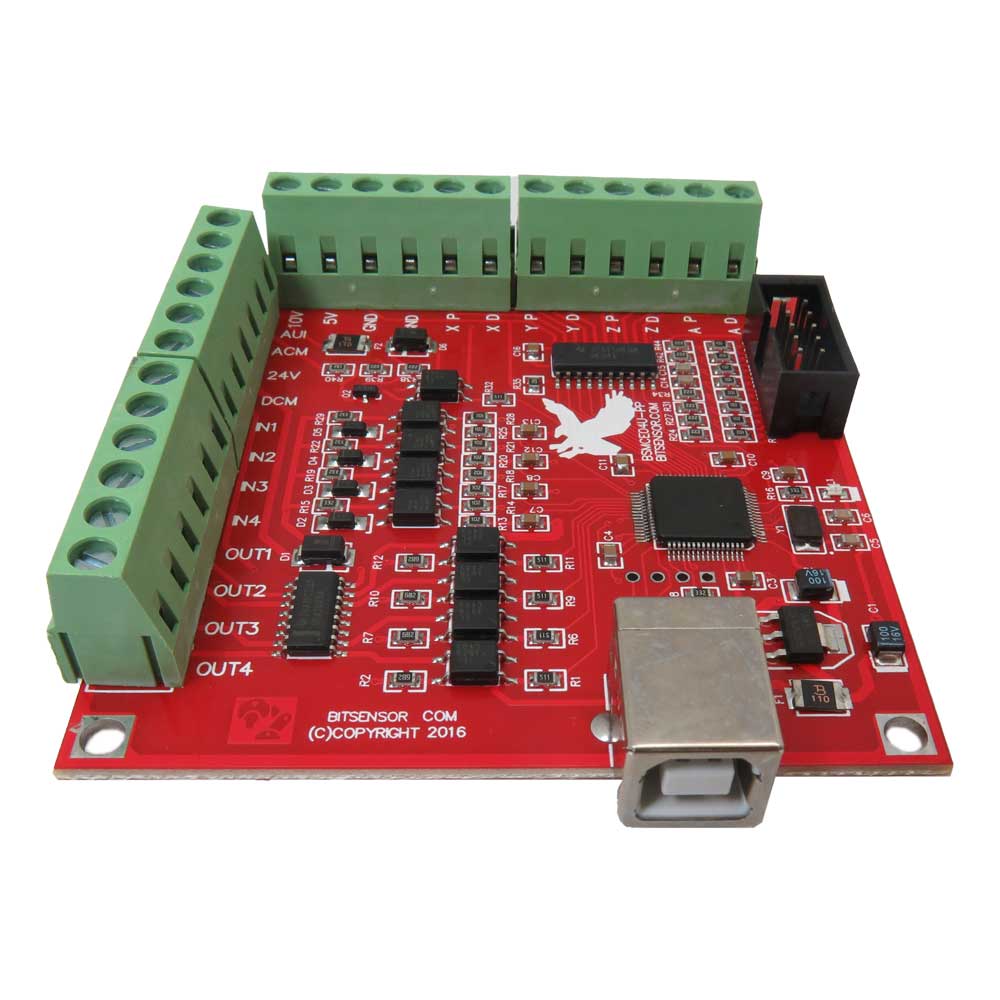

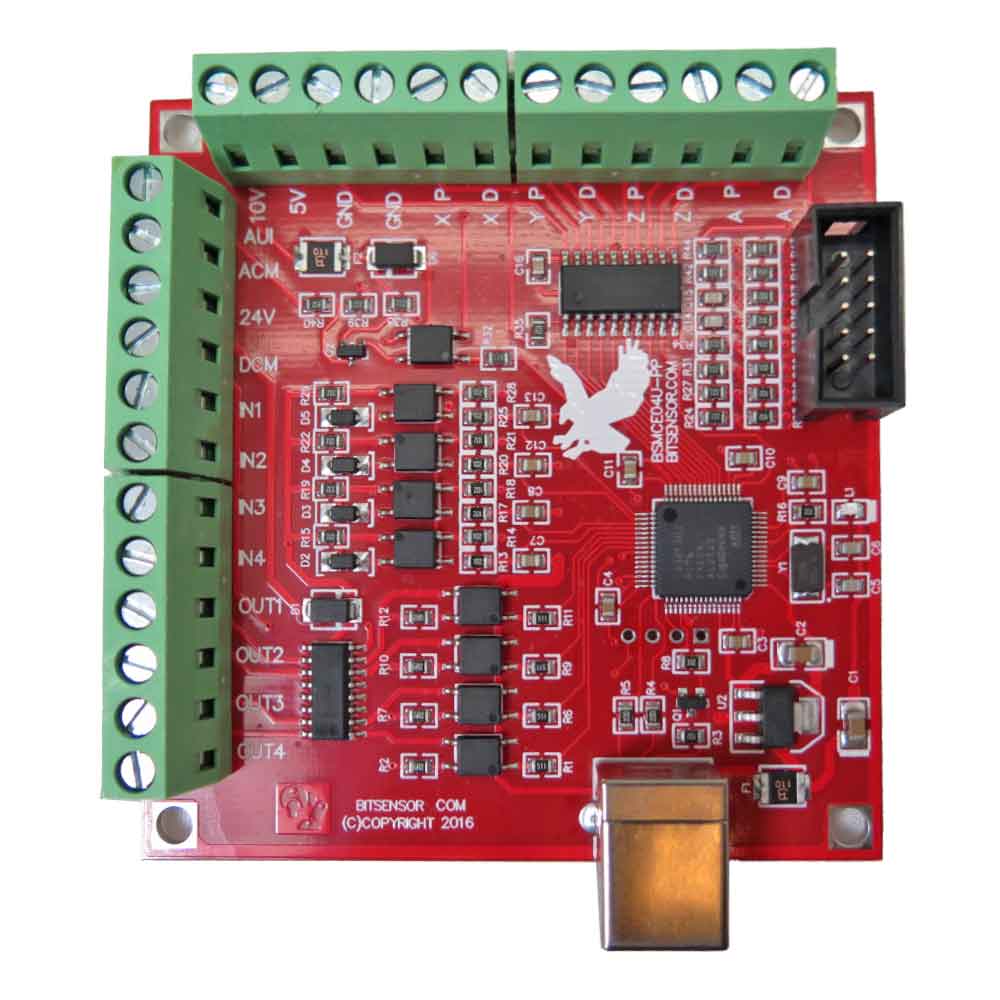

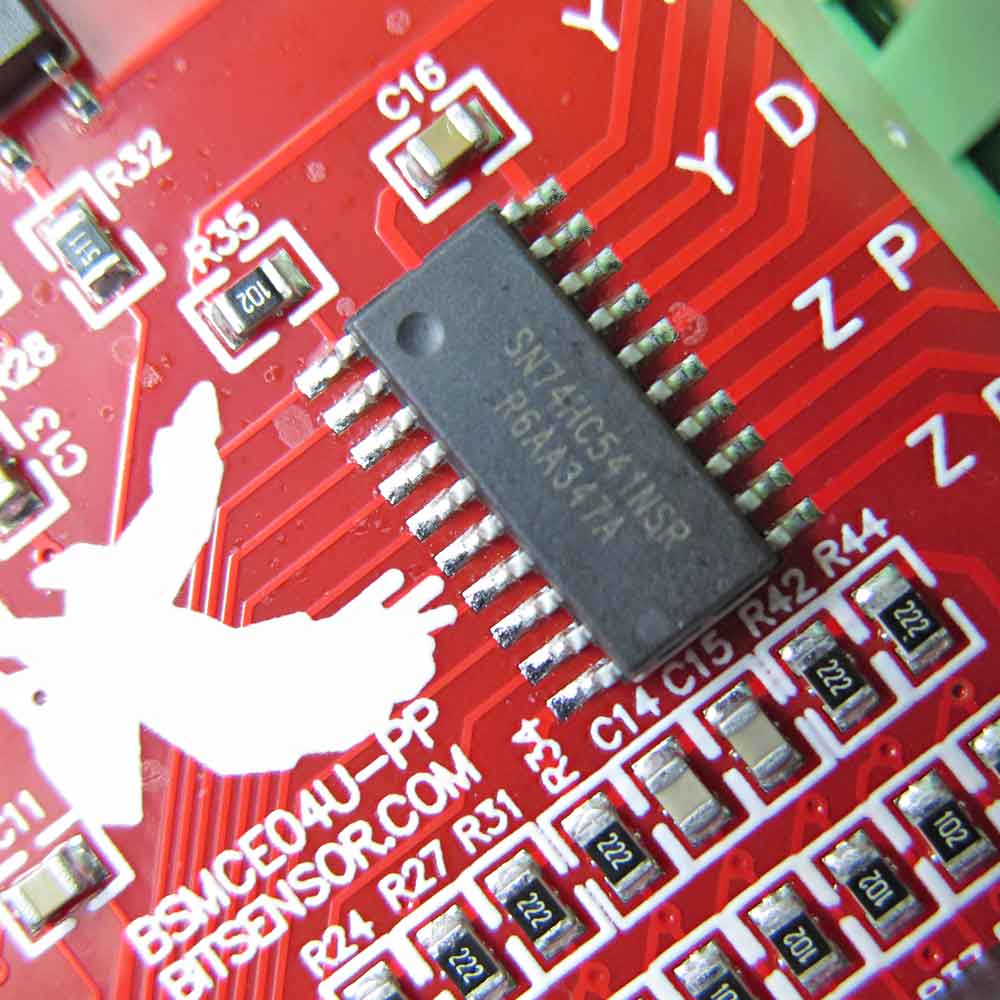

کارت کنترلر دستگاه CNC چهار محور با پشتیبانی از نرم افزار USB MACH3 و پالس خروجی 100KHz

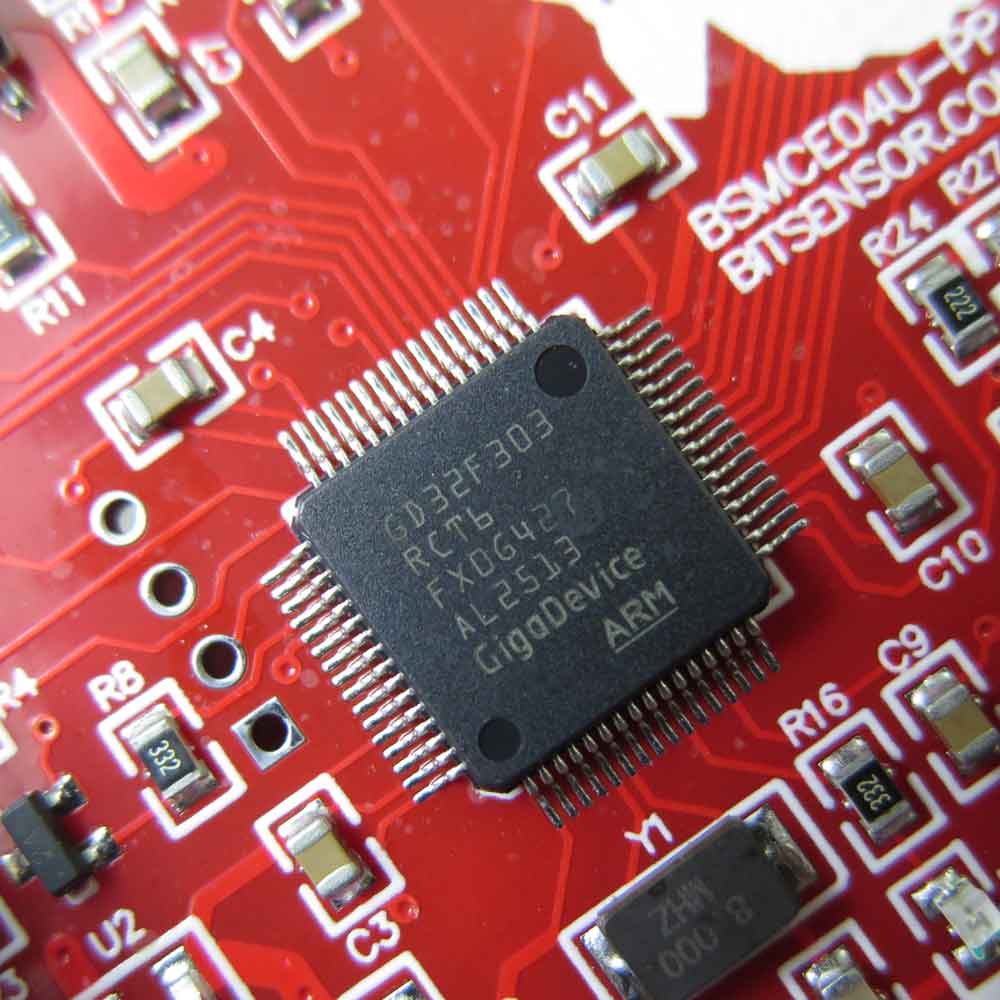

کنترلر CNC وظیفه فرماندهی را برعهده دارد که به روش های گوناگون در ماشین سی ان سی به کار می روند. کنترلر سی ان سی عهده دار وظیفه کنترل اتوماتیک ماشین سی ان سی است که دارای انواع بسیاری است. این برد از نرم افزار قدرتمند MACH3 برای راه اندازی بهره میبرد و توسط آن میتوان حداکثر 4 عدد موتور پله ای را به صورت همزمان کنترل کرد. این برد بر خلاف کنترلرهای MACH3 حرفه ای و صنعتی که اغلب از طریق کابل پرینترهای قدیمی پارالل (LPT) به کامپیوتر متصل می شوند، از پورت USB استفاده می کند از این رو برای اتصال به لپ تاپ و سیستم های جدید مناسب است. کنترلر مچ تری ( Mach3 ) یک کنترلر بر مبنای پی سی بیس PC Base می باشد و تمامی امکاناتی را که یک کنترلر قدرتمند نیاز دارد درون خود دارد.

برد Smooth Stepper با واسط یو اس بی USB یا LAN سرعت انتقال دیتا و امنیت دیتا را بالا برده و با بافر کردن اطلاعات خروجی بسیار خوبی برای درایوها آماده می نماید.

Mach3 دارای یک محیط برنامه نویسی اسکرین Screen جهت طراحی صفحه بصورت شخصی و دلخواه می باشد.

دارای فرکانس کاری 100کیلو هرتز می باشد و قابلیت کار با سرو موتور Servo motor و استپ موتور Step motor را نیز دارد. ورودی و خروجی برای Home Switch و Limit Switch ها را دارد و از تمامی جی کد G Code های استاندارد دستگاه های سی ان سی CNC پشتیبانی می نماید.

کارت کنترلی ارایه شده دارای نمایشگر جهت نمایش وضعیت دستگاه نیز می باشد.

امکان ماکرو نویسی VBscript برای ایجاد دستور ها و فرامین خاص در دستگاه ها وجود دارد و همچنین این ویژگی، کم و زیاد کردن دور اسپیندل و استفاده از تعویض ابزار را فراهم می کند.

کاربرد کارت کنترلر سی ان سی :

- ماشین CNC

مشخصات کارت کنترلر CNC چهار محور:

- 4 محوره، شما می توانید چهار درایور استپر موتور یا سروو متصل کنید.

- پالس گام حداکثر فرکانس 100 کیلوهرتز است که برای سروو موتور یا استپر موتور مناسب است.

- پشتیبانی از ابزار کاوشگر خودکار

- پشتیبانی از ورودی تماس اضطراری

- پشتیبانی از سوئیچ محدود

- پشتیبانی از اتصال چرخ دستی الکترونیکی

- برای ایزوله کردن USB و پورت خارجی و پایدار کردن سیستم باید از منبع تغذیه 24 ولت DC خارجی استفاده کنید.

- می توانید از نرم افزار mach3 برای کنترل سرعت اسپیندل موتور استفاده کنید.

- 1 STATUS INDICATOR، وضعیت اتصال را روی برد نشان می دهد.

مستندات:

اطلاعات راه اندازی کنترلر USB MACH3

Description:

The CNC controller is the brain of a CNC system. A controller completes the all-important link between a computer system and the mechanical components of a CNC machine. The controller's primary task is to receive conditioned signals from a computer or indexer and interpret those signals into mechanical motion through motor output. There are several components that make up a controller and each component works in unison to produce the desired motor movement.

The CNC Controller or CNC Control is the package of electronics and software that takes input either from the g-code or the CNC control panel and converts it to the signals the CNC machine’s motors need to move the CNC axes.

This USB Controller will run Mach3 through a standard USB port on a PC. Mach 3 is the most popular CNC Controller at the low-end, with 47% market share.

The inverter interface (AVI +, AVI-) is isolated from the computer and the main control circuit, and the anti-interference ability is extremely strong. It will not cause interference signals to enter due to the introduction of external strong electrical equipment. This interface can output 0 ~ 10V analog signal, and can also be configured as 0 ~ 5V output.

Note: An additional power source is required for the limit switches and spindle portion of the board.

Application:

CNC machine

Features:

1. Support for 4-axis communication, you can connect four stepper motor drives or servos;

2. Maximum frequency step pulse is 100 KHz, which is suitable for servo or stepper motor;

3. Support automatic probe tool

4. Support Emergency Call Input

5. Support for limit switch

6. Support connect electronic handwheel

7. You must use an external 24 V DC power supply to isolate the USB and external port, and to make the system more stable.

8. Have 0-10 In the output port, you can use the mach3 software to control the spindle speed of the motor.

9. 4 general-purpose inputs, you can connect the limit switch, estop switch, sensor switch, go back to zero and other devices

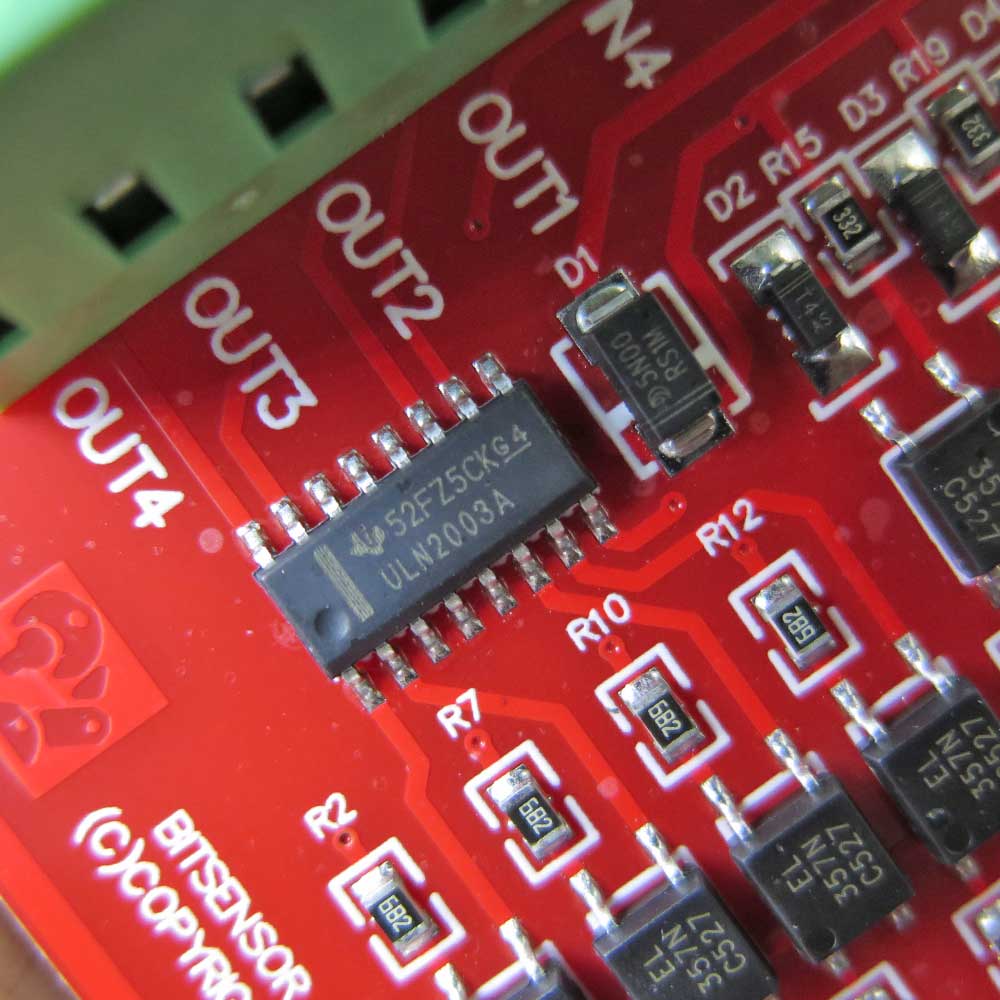

10. 4 general-purpose isolated relay drive output interface, can control four relays to control the spindle starts, forward rotating and reverse rotation, pumps and other devices;

11. 1 STATUS INDICATOR, indicate the connection status on the board.