97,590 تومان

کالا موجود استموجودی انبار : 85 عدد

علاقه مندان : 4 نفر

وضعیت : فعال

تعداد مرجوعی : 0

دنبال کنندگان : 7 نفر

قدمت : 6 سال و 8 ماه و 26 روز

وزن : 25 گرم

کل فروش : 1669 عدد

تعداد سفارش ها : 248 سفارش

5 از 5.0 با 1 رای

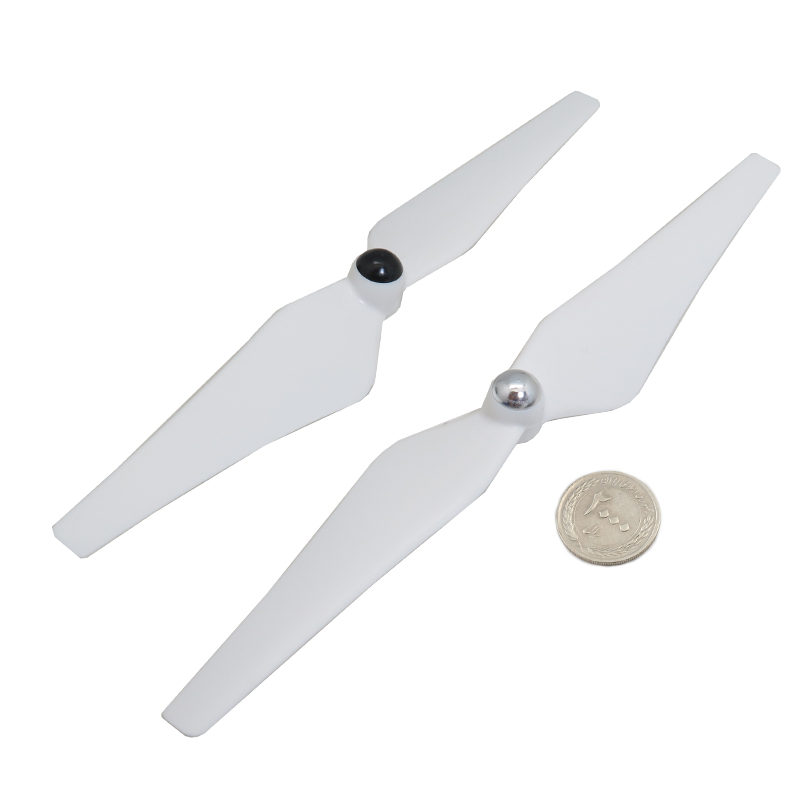

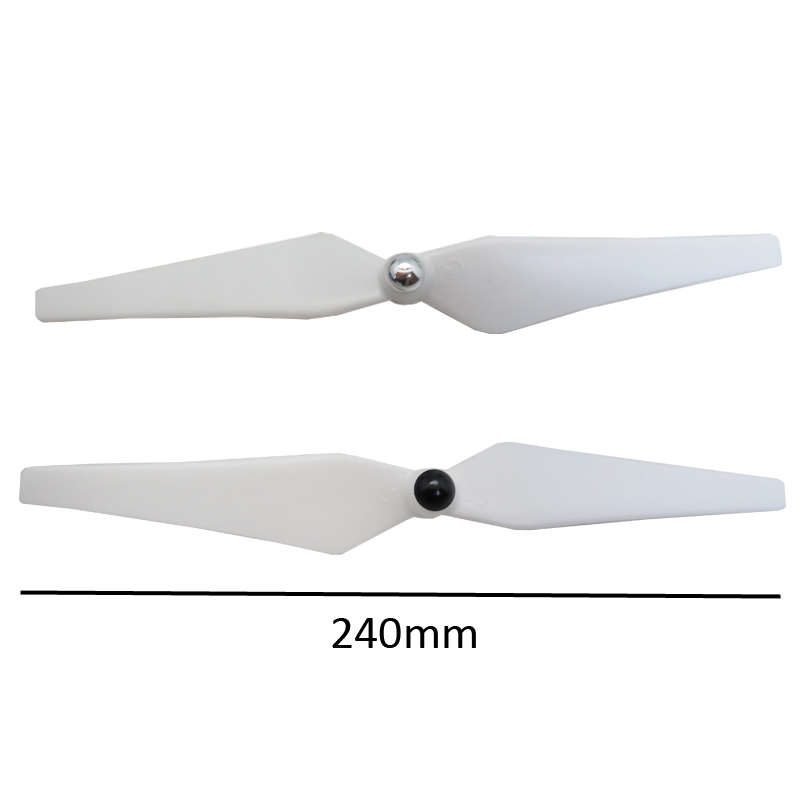

ملخ (پولر و پوشر) 9450 مناسب فانتوم های DJI

ملخ، بال ربات پرنده شماست. با چرخش ملخ یک نیروی جلوبرنده ایجاد می شود که به آن تراست می گویند. در واقع نیروی تراست در اثر اختلاف فشار ایجاد شده بین سطح پشت و روی ملخ به وجود می آید. ملخ ها بر اساس مشخصات هندسی و شکل ظاهری انواع مختلفی دارند.

مهم ترین ویژگی های ظاهری یک ملخ شامل قطر، تعداد و فرم تیغه ها هستند. عموما ملخ ها بر اساس اندازه قطر و گام حرکت معرفی می شوند. گام یک ملخ مقدار جا به جایی ملخ به ازای یک دور چرخش به دور خودش است که وابسته به فرم و سطح موثر تیغه ها است.

ملخ در کوادکوپتر تنها بخش آیرودینامیکی است که وظیفه شناور کردن دستگاه را در هوا برعهده دارد، از این رو انتخاب صحیح ملخ با توجه به دور موتور و قدرت موتور حائز اهمیت می باشد، انتخاب یک ملخ مناسب و با کیفیت عالی علاوه بر اینکه در مصرف انرژی صرفه جویی می کند، در کیفیت پرواز دستگاه نیز تعیین کننده است.

ملخ ها خود دو نوع هستند پولر و پوشر (دمنده و مکنده) که برای کواد باید دو جفت (هر جفت یک پولر و پوشر) تهیه کرد. بهتر است ملخی که برای ساخت کوادکوپتر استفاده می کنید مدل پولر پوشر (puller pusher propeller) یا به اصطلاح ملخ های دمنده مکنده باشند.

این ملخ که از نوع پولر پوشر مدل 9450 دارای طول 9.4 اینچی، برای فانتوم های DJI مناسب است. این ملخ از جنس نایلون یا پلاستیک می باشد.

کاربرد ملخ 9450 :

- در کوادکوپتر

مشخصات ملخ پولر و پوشر:

- این ملخ از جنس نایلون یا پلاستیک می باشد.

- طول محصول: 9.4 اینچ

Description:

Propeller driven aircraft to require designers to choose early in the design process to use a pusher configuration or a puller configuration. Each layout has its advantages and disadvantages and as with all design choices selecting one or the other is dependent on the underlying design goals.

In the days of electric motors, which can spin in either direction with no problems, there won't be any difference between pusher or puller props. Back when gas was more popular, and most engines could only spin in one direction, you would need a pusher prop if the engine was in the back of the plane.

Pushers are generally seen as more efficient, other than that, there's not a lot of difference. Propellers can be positioned in the middle of the plane for several reasons, most common probably being ease of balancing the plane and adding protection to the propeller.

Fundamentally the performance of pusher aircraft is like that of puller aircraft with similar power outputs and weights. The difference is how efficiently the propulsion layout and the basic aerodynamic design achieves this performance. Runway performance can be affected by the pusher configuration and is also worth considering.

The direction of rotation does create a swirl in the prop wash downstream of the propeller. This will have an impact on most planes. Most conventional puller planes will need the right thrust or right rudder to keep them straight during a high power climb. There are many reasons for this but they all trace back to torque, the direction of the prop wash swirl, and something called P-factor. If you use a reverse rotation propeller you will want left thrust or left rudder instead. If the prop is in the back, and there is nothing behind it, then prop swirl won't matter, but the torque and possibly P-factor still will. Planes with single propellers are not perfectly symmetrical, just close. Usually, the difference is just a click or two of trim, but some designs are more problematic than others.

Particularly for air-cooled piston engines, engine cooling in the pusher configuration can be difficult to achieve. The same turbulent air disrupting flow to the propeller also disrupts the flow to cooling intakes. Puller layout aircraft have the advantage of unobstructed cooling intakes and even some propulsive thrust to maintain engine temperatures, resulting in potentially lower climb speeds for the same ambient conditions.

Puller engine layouts provide superior cooling flow to piston engines thanks to unobstructed cooling intakes.

Features:

Product Name: 9450 special propeller

Product Length: 9.4 inches

Pitch: 5.0 inches

Suitable Models: DJI Genie II, III, F450 F500 F550, etc.

Product Material: nylon